A Practical Guide to Material Handling and Assembly Lines: Understanding Conveyor Systems

Smooth and efficient material handling is essential for modern manufacturing and production. Assembly lines and conveyor systems help move materials, components, and finished products seamlessly throughout a facility. For companies looking for custom solutions, SPG Conveyor Systems—a trusted UK manufacturer specializes in designing, delivering, and installing conveyor systems, components, and sortation equipment.

What is Material Handling and Why is it Important?

Material handling encompasses the movement, storage, control, and protection of materials and products during manufacturing, distribution, and disposal. It ensures efficiency, reduces waste, and improves safety in production environments. In assembly lines, the right conveyor and conveying system is critical to maintain productivity and accuracy.

Whether dealing with raw materials, automated test equipment, or finished goods, SPG Conveyor Systems provides solutions that cater to the unique needs of various industries. From robotic production lines to pneumatic conveying systems, the importance of tailored conveyor belt components cannot be overstated.

Types of Conveyors for Material Handling and Assembly Lines

Selecting the right conveyor system depends on your production process and specific operational needs. Below are some of the most commonly used conveyor types in material handling and assembly environments:

1. Belt Conveyors

Belt conveyors are one of the most adaptable options for material handling. They efficiently move products of various weights, making them a popular choice in manufacturing and distribution settings.

- Perfect for: Moving packaged goods, raw materials, and bulkier items.

- Customization: SPG Conveyor Systems specializes in tailored belt conveyor solutions.

2. Pneumatic Conveyors

Pneumatic conveyors rely on air pressure to transfer materials through sealed pipelines. They are particularly effective for handling fine, granular, or powdered substances.

- Common uses: Industries such as pharmaceuticals, food production, and chemical processing.

- Benefits: Ensures clean, dust-free transport with minimal contamination risk.

3. Sortation Conveyors

Sortation conveyors efficiently identify, separate, and redirect products to designated areas within a facility. These systems are critical for high-volume distribution centers and e-commerce operations.

- Common applications: Used in parcel sorting, warehouse automation, and logistics.

- Technology integration: SPG provides advanced sortation systems designed to work seamlessly with robotic automation.

4. Modular Belt Conveyors

Instead of a single continuous belt, modular belt conveyors utilize interlocking plastic segments. This design enhances durability while simplifying maintenance.

- Industry applications: Frequently used in food and beverage processing due to their hygienic properties.

- Customization: Configurable layouts allow for easy adaptation to different product handling needs.

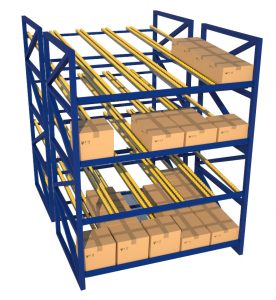

5. Roller Conveyors

Roller conveyors offer an efficient and economical method for transporting heavy loads. They can be gravity-driven or motorized, depending on the application.

- Where they are used: Common in warehouse operations, assembly lines, and manufacturing facilities.

- Customization options: Adjustable configurations to fit diverse spatial and operational requirements.

6. Rotary Tables

Rotary tables help manage product flow by temporarily holding or transferring items between conveyor lines. These are particularly useful for assembly, sorting, or buffering processes.

- Best suited for: Organizing, staging, or redirecting materials in production environments.

Types of Conveyor Components and Their Uses

A conveyor system in material handling and assembly lines are only as effective as their components. The right conveyor belt components ensure smooth operation and long-lasting performance. Here are some of the most common conveyor components and their applications:

1. Belts

- Purpose: The main element of any conveyor system, belts carry materials or products from one point to another.

- Types: Rubber, plastic, or metal belts depending on the application.

- Applications: Ideal for industries like packaging, food processing, and manufacturing.

2. Rollers

- Purpose: Provide support and movement for the conveyor belt.

- Types: Drive rollers, return rollers, and impact rollers.

- Applications: Used in both powered and gravity-driven conveyor systems.

3. Pulleys

- Purpose: Drive the belt and maintain tension.

- Types: Drive pulleys and tail pulleys.

- Applications: Essential for maintaining the efficiency of belt conveyors.

4. Motors and Drives

- Purpose: Power the movement of the conveyor belt or rollers.

- Applications: Used in automated systems for consistent and controlled operations.

5. Frames and Supports

- Purpose: Provide the structure and stability for the conveyor system.

- Applications: Customizable to fit unique production layouts and environments.

6. Idlers

- Purpose: Support the belt and help maintain its alignment.

- Applications: Used in longer conveyor systems to prevent sagging and misalignment.

7. Control Systems

- Purpose: Automate and regulate the speed, direction, and operations of the conveyor.

- Applications: Ideal for robotic production lines and automated test equipment.

Key Benefits of Using Bespoke Conveyor Systems

SPG Conveyor Systems specializes in delivering bespoke solutions tailored to your industry’s requirements. Here’s why investing in a customized conveyor and conveying system can transform your operations:

- Efficiency: Increased speed and accuracy in material handling and assembly.

- Reliability: Durable systems designed for long-term use with minimal maintenance.

- Flexibility: Modular designs that adapt to your evolving needs.

- Expert Support: From design to installation, SPG offers end-to-end services.

How SPG Conveyor Systems Stands Out

As one of the top conveyor belt manufacturers and conveyor companies in the UK, SPG Conveyor Systems is committed to excellence. We deliver high-quality conveyor belt systems, material handling equipment conveyors, and conveyor belt components to clients across various industries. With a focus on innovation, our solutions integrate advanced technologies like automated test equipment and robotic production lines to enhance efficiency and productivity.

Our expertise includes:

- Custom Design: Bespoke systems tailored to your specific requirements.

- Complete Services: From design and manufacturing to delivery and installation.

- Reliable Components: High-quality conveyor belt components for maximum durability.

Last Notes

In today’s fast-paced manufacturing landscape, efficient material handling and assembly lines are essential for success. By choosing the right conveyor system—whether it’s a pneumatic conveyor system, belt conveyor, or sortation conveyor—you can streamline operations and improve productivity. SPG Conveyor Systems, as a trusted UK manufacturer, is here to help you find the perfect solution for your business.

If you’re looking for conveyor belt suppliers, conveyor belt manufacturers, or bespoke solutions for material handling equipment conveyors, contact SPG Conveyor Systems today. Let us design, deliver, and install the ideal system for your needs.

You can also find this article here.

Learn more about how to reduce labor costs by automating your system.